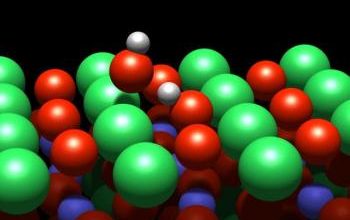

LayTec’s new InspiRe in-situ tool used for monitoring perovskite formation

Germany-based in-situ metrology system maker LayTec has announced that its new InspiRe system applies high-speed in-situ reflectance measurements for monitoring perovskite thin-film formations during spin-coating and subsequent annealing. In collaboration with professor Norbert Nickel’s group at HZB, LayTec designed the InspiRe in-situ metrology system, which was applied to monitor both spin-coating and annealing. Gathering data at a time resolution on the millisecond scale allows resolving of the kinetics and phase formations during film formation. While spin-coating, the absorption behavior and the thinning of precursor solution is monitored. The absorption edge (i.e. band gap) of the deposited perovskite film is derived directly during annealing. Spectral changes during annealing indicate âover-annealing’ after the desired bandgap has been achieved. This methodology allows the systematic study of film formation during two crucial process steps…

Germany-based in-situ metrology system maker LayTec has announced that its new InspiRe system applies high-speed in-situ reflectance measurements for monitoring perovskite thin-film formations during spin-coating and subsequent annealing.

In collaboration with professor Norbert Nickel’s group at HZB, LayTec designed the InspiRe in-situ metrology system, which was applied to monitor both spin-coating and annealing. Gathering data at a time resolution on the millisecond scale allows resolving of the kinetics and phase formations during film formation.

While spin-coating, the absorption behavior and the thinning of precursor solution is monitored. The absorption edge (i.e. band gap) of the deposited perovskite film is derived directly during annealing. Spectral changes during annealing indicate âover-annealing’ after the desired bandgap has been achieved.

This methodology allows the systematic study of film formation during two crucial process steps for identifying optimization routes and for implementing a rigid quality control scheme for upscaling and industrialization.

semiconductor-todayPerovskite-InfoPerovskite applicationsPerovskite SolarTechnical / research

Above are LayTecâs new InspiRe in-situ tool used for monitoring perovskite formation web publication,Hope can help you.

Arc Melting in Glovebox

Details Quantity: 5 – 20 g per charge Temperature: up to 3500°C, depending on quantity Generator: outside of glovebox Connection: 230 V / 50/60 Hz (different voltage on request) Crucible plate: standard crucible plate or customized crucible plates Options: Special cold crucible (suction casting), Vacuum pump, Turbomulecular pumping system HVT52/G, High vacuum gauge, Water flow control, Recirculating chiller Description For oxygen-sensitive samples to be handled and alloyed in inert gas atmosphere • Melting chamber and movable electrode inside of glovebox • Generator, vacuum pump and operating panel at the outside • Designed for melting samples of approx. 5-20 g up to 3500°C, sufficient for most laboratory purposes • Small melting chamber ensures fast evacuation and low gas consumption • Freely movable, water-cooled electrode • Dismountable, water-cooled copper crucible plate with…